installation manual of tumbler screeners

Tumbler screeners are industrial machines used for separating materials by size, ensuring efficiency and precision in various processes․ They play a crucial role in maintaining product quality․

1․1 What Are Tumbler Screeners?

Tumbler screeners are industrial machines designed to separate materials into different sizes or grades․ They consist of a cylindrical drum with perforated screen mesh, rotating to tumbling effect․ Widely used in pharmaceutical, food, and chemical industries, they ensure precise separation of powders, granules, and other materials․ Their efficiency and durability make them essential for maintaining product quality and consistency in various production processes․

1․2 Importance of Proper Installation

Proper installation of tumbler screeners is critical for ensuring optimal performance, safety, and longevity․ Incorrect installation can lead to mechanical failures, inefficiency, and potential safety hazards․ It guarantees compliance with industry standards and manufacturer specifications, ensuring smooth operation and minimal downtime․ Proper setup also prevents damage to the equipment and materials, making it essential for maintaining productivity and reliability in industrial processes․

Pre-Installation Checklist

A pre-installation checklist ensures all necessary steps are completed before starting the setup․ It includes verifying equipment condition, reviewing manuals, and preparing the site and tools․

2․1 Site Preparation Requirements

Proper site preparation is crucial for safe and efficient installation․ Ensure the area is level, clear of obstructions, and has adequate drainage․ The foundation must be stable and even to prevent vibration issues․ Verify that utilities like electricity and water are accessible․ Maintain sufficient clearance around the screener for maintenance and operation․ Check for any underground hazards and ensure the site meets all safety and environmental regulations before proceeding․

2․2 Tools and Equipment Needed

Essential tools include wrenches, screwdrivers, and hoisting equipment for safe handling․ Ensure availability of measuring tools like levels and tape measures․ Protective gear such as gloves and safety glasses is mandatory․ Power tools like drills and impact wrenches may be required for assembly․ Additionally, have spare parts and lubricants on hand․ Proper equipment ensures efficient and secure installation, minimizing downtime and potential risks during the process․

2․3 Safety Precautions

Always wear personal protective equipment, including gloves and safety glasses․ Ensure the installation area is clear of hazards and well-ventilated․ Use proper lifting techniques to avoid injury․ Secure the screener firmly to prevent movement during operation․ Follow all manufacturer guidelines for electrical connections․ Keep loose clothing and long hair tied back․ Never operate machinery near flammable materials․ Ensure all personnel are trained and aware of potential risks․ Safety is paramount for a successful installation․

Unloading and Placing the Screener

Safe unloading and correct placement are crucial․ Use suitable tools and follow safety guidelines to prevent damage or harm during installation․ Proper positioning ensures smooth operation․

3․1 Safe Unloading Techniques

Safe unloading involves proper planning and equipment․ Use cranes or forklifts with securing straps to prevent movement․ Ensure the ground is level and stable․ Assign a team to guide the process, and use hand signals for clear communication․ Avoid sudden movements to prevent accidents․ Secure the screener firmly to the transport vehicle or ground during unloading․ Always follow manufacturer guidelines and safety protocols to minimize risks and ensure a smooth transition to the installation site․

3․2 Positioning the Screener

Positioning the screener requires careful planning to ensure optimal performance․ Place it on a level, stable surface, ideally concrete or gravel, to maintain balance․ Align the screener with the material flow direction and ensure it is accessible for maintenance․ Check manufacturer specifications for recommended placement and spacing․ Secure the unit firmly to prevent movement during operation․ Proper positioning ensures efficient screening and minimizes wear on the equipment․ Always verify alignment before startup․

Electrical and Power Connections

Ensure all electrical connections are secure and meet manufacturer specifications․ Connect power supplies according to voltage and current requirements․ Test circuits for proper function and safety․

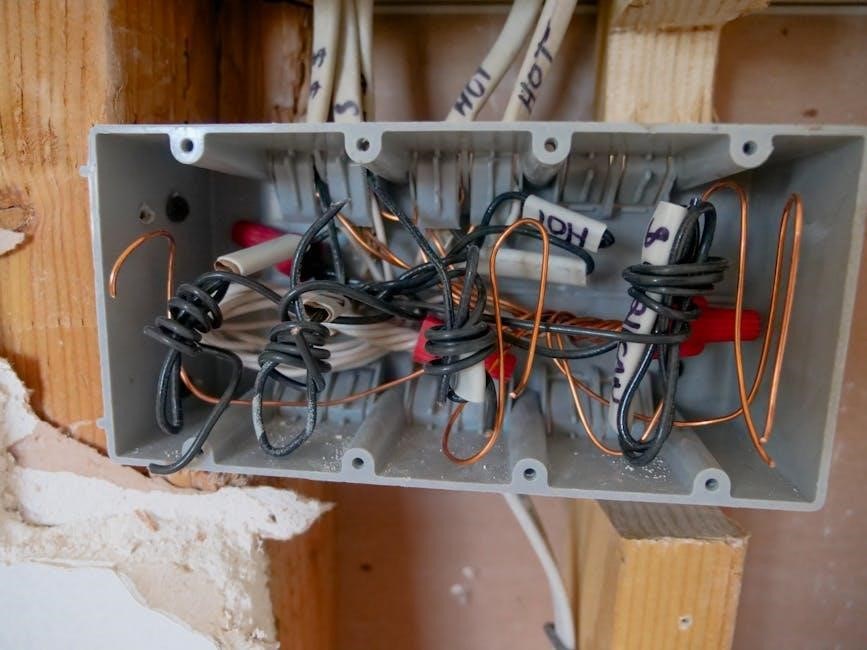

4․1 Connecting Power Supplies

Connect the power supply to the screener, ensuring the voltage matches the equipment’s specifications․ Verify all electrical connections are secure and properly insulated․ Use appropriate cables and connectors to prevent power loss or short circuits․ Check the circuit breaker or fuse box to ensure it can handle the screener’s power requirements․ Always follow the manufacturer’s wiring diagram and safety guidelines to avoid electrical hazards․

4․2 Testing Electrical Components

After connecting the power supply, test all electrical components to ensure proper functionality․ Use a multimeter to verify voltage and current levels․ Check for any short circuits or open connections․ Test the motor and control panel to confirm they operate smoothly․ Ensure all safety features, such as emergency stop buttons, are functioning correctly․ Record any issues and address them before proceeding with the installation․

Assembling the Screener

Assemble the tumbler screener by attaching the drum, installing the screen mesh, and securing all components tightly․ Ensure proper alignment and connection of accessories for optimal functionality․

5․1 Attaching the Drum

To attach the drum, ensure the screener frame is stable and secure․ Align the drum with the frame’s mounting points, following the manufacturer’s alignment guide․ Use the provided bolts and nuts to fasten the drum, tightening them evenly to avoid imbalance․ Double-check the drum’s position and ensure all connections are snug․ Proper alignment is critical for efficient screening and to prevent operational issues․ Always refer to the manual for specific torque specifications to guarantee safety and performance․

5․2 Installing the Screen Mesh

Begin by removing any protective packaging from the screen mesh․ Carefully align the mesh with the drum’s frame, ensuring it fits snugly and evenly․ Secure the mesh using the provided tension rings or clips, tightening them firmly to prevent movement․ Ensure the mesh is taut and evenly spaced to maintain screening efficiency․ Refer to the manual for specific torque settings or tightening sequences to guarantee a proper fit and optimal performance during operation․

5․3 Adding Accessories

Install any additional accessories, such as feed hoppers, discharge chutes, or cleaning brushes, according to the manufacturer’s specifications․ Ensure all components are securely fastened using the provided hardware․ Align accessories properly to maintain material flow and prevent obstruction․ Tighten all connections firmly and double-check for stability․ Accessories should enhance functionality without compromising the screener’s performance or safety standards․ Follow the manual for specific installation guidelines for each accessory type․

Testing the Screener

Testing the screener ensures proper functionality and prepares it for operation․ Conduct thorough checks of all components, including motor performance and screen efficiency, to guarantee reliability․

6․1 Initial Startup and Testing

During initial startup, ensure all safety precautions are in place․ Power up the screener gradually, monitoring for unusual noises or vibrations․ Test with a small material sample to observe separation accuracy and throughput․ Verify that all components function as intended, addressing any discrepancies immediately to prevent operational issues later․ This step ensures smooth and reliable performance before full-scale operation begins․

6․2 Calibrating the Screener

Calibration ensures the screener operates accurately and efficiently․ Begin by adjusting the machine settings according to the material specifications․ Run test cycles to verify the screening accuracy and consistency․ Fine-tune the vibrational amplitude, speed, and angle as needed․ Regular calibration prevents material wastage and ensures optimal performance․ Document the final settings for future reference and maintenance․

Final Checks and Handover

Conduct a thorough inspection of the screener to ensure all components are functioning correctly․ Review the installation and testing phases for compliance․ Provide detailed operating manuals and training to personnel․ Confirm that all safety and operational protocols are understood before final handover to the user․

7․1 Conducting a Final Inspection

A final inspection ensures all components of the tumbler screener are properly installed and functioning as intended․ Check the mechanical integrity, electrical connections, and safety features․ Verify that all moving parts are lubricated and aligned correctly․ Inspect the screen mesh for damage or misalignment․ Test the screener under load to ensure it operates smoothly and meets performance expectations․ Document any findings and address them before final approval․

7․2 Providing Operating Documentation

Providing comprehensive operating documentation ensures smooth operation and maintenance of the tumbler screener․ Include detailed manuals, safety guidelines, and troubleshooting tips․ Specify maintenance schedules, parts lists, and warranty information․ Clear documentation helps operators understand proper usage, maximizing efficiency and safety․ Ensure all materials are easily accessible and understandable for personnel․ This step is crucial for long-term functionality and compliance with safety standards․

7․3 Training Personnel

Training personnel is essential for ensuring the tumbler screener operates efficiently and safely․ Provide detailed instructions on startup procedures, operational parameters, and emergency shutdown protocols․ Emphasize safety protocols and proper handling techniques to prevent accidents․ Hands-on training sessions should be conducted to familiarize staff with the equipment․ Additionally, ensure personnel understand routine maintenance tasks and troubleshooting methods․ This ensures smooth operation and minimizes downtime․

Include role-specific training to address individual responsibilities․ This fosters a skilled workforce capable of managing the screener effectively․ Continuous updates and refresher courses are recommended to keep personnel informed of new features or operational changes․ Proper training not only enhances productivity but also ensures compliance with safety standards and operational best practices․

Troubleshooting Common Issues

Address common problems like vibration, noise, or material blockages․ Check balance, lubrication, and screen condition․ Refer to the manual for diagnostic steps and solutions․

8․1 Identifying and Solving Installation Problems

During installation, common issues like misalignment, improper electrical connections, or incorrect drum assembly may arise․ Conduct a thorough inspection to identify these problems․ Use diagnostic tools to check for error messages or unusual vibrations․ Refer to the manual for troubleshooting guides․ Ensure all components are securely fastened and power sources are correctly connected․ Addressing these issues promptly ensures smooth operation and prevents future malfunctions․